TSF STABILITY MONITORING

Coda-Wave Interferometry (CWI) for Tailings Storage Facilities (TSF) Stability Monitoring deploying a network of Seismic Noise Monitoring Stations

Tailings Dams

Tailings storage facilities are some of the most challenging structures to operate in the mining industry. These structures fail far more regularly than normal water-storage dams (Azam and Li, 2010). Many of these structures are susceptible to liquefaction and piping failure. Therefore, they need to be monitored carefully.

Currently, most geophysical techniques used to monitor these structures only provide point measurements (piezometers, flow meters and CPTu). As a result, these techniques can easily miss the early signs of failure, where the zone of degradation could be small and localised.

In collaboration with the Institute of Mine Seismology (IMS), Golden Taurus Ingeniería (GTI) delivers cutting-edge solutions and services to the mining industry, using advanced Coda-Wave Interferometry (CWI) for continuous tailings dams stability monitoring. This technology helps ensure safety and prevent potential hazards.

Currently, most geophysical techniques used to monitor these structures only provide point measurements (piezometers, flow meters and CPTu). As a result, these techniques can easily miss the early signs of failure, where the zone of degradation could be small and localised.

In collaboration with the Institute of Mine Seismology (IMS), Golden Taurus Ingeniería (GTI) delivers cutting-edge solutions and services to the mining industry, using advanced Coda-Wave Interferometry (CWI) for continuous tailings dams stability monitoring. This technology helps ensure safety and prevent potential hazards.

In some cases, radars and/or high-resolution cameras are used to monitor small deformations on the dam walls. Unfortunately, these methods measure surface perturbations and are incapable of detecting internal changes within the walls.

Of further concern with current monitoring technology is the poor performance during heavy rainfall. Small deformations on the dam wall become very difficult to detect due to the fluid on the surface of the wall. Similarly, seepage flow rates are difficult to interpret during heavy rainfall due to rain flowing down the embankment, contaminating the measurements. These limitations are unfortunate, as heavy rain has been known to be a significant contributing factor to tailings dam wall failure (Azam and Li, 2010).

Of further concern with current monitoring technology is the poor performance during heavy rainfall. Small deformations on the dam wall become very difficult to detect due to the fluid on the surface of the wall. Similarly, seepage flow rates are difficult to interpret during heavy rainfall due to rain flowing down the embankment, contaminating the measurements. These limitations are unfortunate, as heavy rain has been known to be a significant contributing factor to tailings dam wall failure (Azam and Li, 2010).

In recent years, ambient seismic noise interferometry has been used to monitor the time-dependent behaviours of environments such as volcanoes, landslides, underground mines, geothermal reservoirs and active faults zones. Additionally, laboratory experiments have shown that this method is able to detect internal erosion (piping failure) in earthen embankments (Planès et al., 2016). This method essentially uses ambient seismic vibrations to create virtual seismic sources (Curtis et al., 2006).

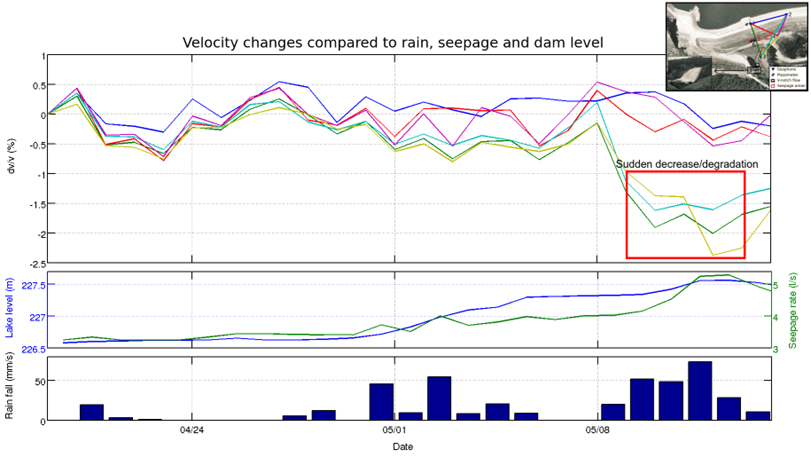

Pioneering work by IMS has revealed that this method can be used to monitor with remarkable accuracy the stability of tailings dams over time (Olivier et. al., 2017). The study showed that subtlechanges in seismic velocity can reveal internal erosion and increased seepage during a period of heavy rainfall, even when other geophysical instruments could not.

IMS manufactures a number of different sensors and seismometers purpose built for monitoring of tailings dams. The xES is a low footprint solutions custom-built for such applications. Our partner IMS is also able to provide distributed acoustic sensing (DAS) solutions for monitoring of tailings dams.

IMS manufactures a number of different sensors and seismometers purpose built for monitoring of tailings dams. The xES is a low footprint solutions custom-built for such applications. Our partner IMS is also able to provide distributed acoustic sensing (DAS) solutions for monitoring of tailings dams.

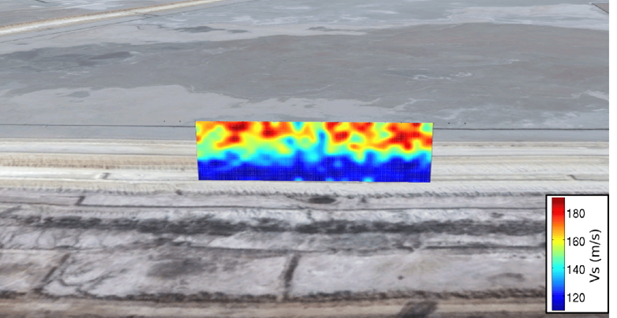

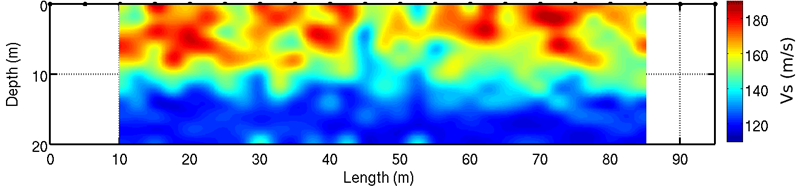

Furthermore, IMS has demonstrated that ambient noise tomography can be used to image the internal structure of tailings dam walls. The high-resolution images can be used to determine the depth of the phreatic surface and to illuminate seepage pathways and internal erosion (Olivier et. al. 2018).

Often an initial ambient noise imaging survey would be performed using a temporary array of seismic nodes to detect the regions of potential instability in the tailings dam wall, followed by ongoing real-time monitoring of the structural integrity of the wall using a permanent setup of xPODs to provide early warnings of potential failure.

Often an initial ambient noise imaging survey would be performed using a temporary array of seismic nodes to detect the regions of potential instability in the tailings dam wall, followed by ongoing real-time monitoring of the structural integrity of the wall using a permanent setup of xPODs to provide early warnings of potential failure.